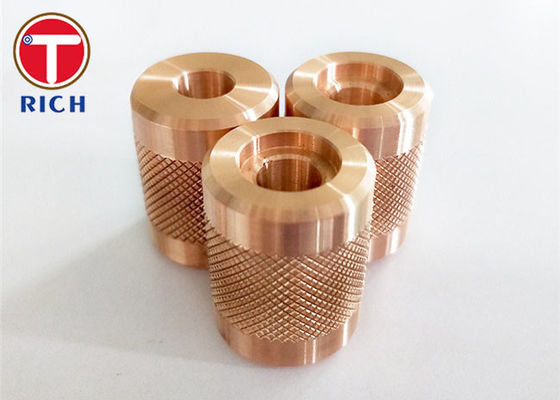

Hardware processing precision copper processing custom CNC CNC lathe processing fasteners non-standard hardware workpiece

Cnc Precision Machining Feature: High machining precision and stable quality. The machining dimensional accuracy is between 0.005 and 0.01 mm, which is not affected by the complexity of the parts. Since most of the operations are done automatically by the bed, human errors are eliminated, and the consistency of the size of batch parts is improved. At the same time, a position detection device is also used on the precision-controlled machine tool, which further improves the precision of precision CNC machining.

Products Discription

| Product name | Machining center cnc turning Hardware processing precision copper processing custom | |

| Production Equipment | CNC, Milling Machine Processing, CNC Lathe Processing,CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding | |

| Material |

Copper, Brass:260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper,etc |

|

|

Drawing format |

STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. | |

| Production Process | Raw material incoming inspection→Drawing Confirmation→Machine Setup→Trial Production→Sample quality check and confirmation→Mass production→Final Inspection→Packing→Ready to Ship | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. |

|

| Application | Auto Parts, Hydraulic Hoses, Oil Machinery, Geological Drilling, MotorCycle, Bycycle, Agricultural Machine Parts, Engineering Machinary, Fastners. | |

| Surface roughness | Ra 0.1~3.2 | |

| Surface Treatment | Grinding, Polish, Deburr, Painting, Galvanization, Chrome Plating, Anodization treatment etc | |

| Inspection | 100% Dimensional Check 100% Visual Check Mechanical Properties Inspection, Internal Lab test report or Third Party Inspection Report. |

|

| Inspection Instrument | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge |

|

|

Tolerance |

Customer's Drawing Request | |

Products Display

![]()

![]()

Production Process

![]()

Our Workshop

![]()

![]()

Quality Control Standards

To consistently exceed customer expectations, quality control and assurance is achieved through

• Comprehensive written procedures and policies

• Detailed records of incoming raw material

• Optional XRF analysis reports

• Analysis of root cause of non-conformances

• Fully equipped inspection department

• Consistent calibration and labeling of inspection tools

• Designated areas for non-conformationg parts

• Staff members being strongly encouraged to suggest improvements in methods, materials and suppliers

Why choose TORICH?

1. Manufacturer, Exporting and Trading for over 20 years' experiences.

2. Good connection with 1st hand manufacturers engineer and production team directly.

3. TOP A raw material supplier for long term and stable cooperation.

4. Experienced engineers in the field for over 20 years.

5. 7x24hours prompt reply after receiving 1st enquiry.

Packing and Transportation

![]()

FAQ